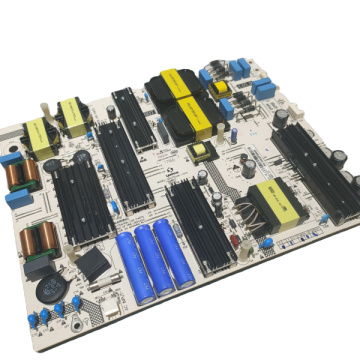

One Stop Pcb Assemby Pcba Prototyping Service

| Unit Price: | 12 USD |

|---|---|

| Min. Order: | 1 Piece/Pieces |

Basic Info

Model No.: PCB surface mount

Product Description

What is a surface mount PCB?

SMT patch refers to the abbreviation of a series of technological processes that are processed on the basis of PCB, which is part of the process of PCBA Manufacturing, and PCB is a printed circuit board. SMT is a surface mount technology (surface mount technology) is the most popular technology and process in the electronics assembly industry. It is a circuit assembly technology that mounts electronic components without leads or short leads on the surface of a printed circuit board or other substrates, and then solders them and PCB assembly by reflow soldering or Wave Solder for PCBA. . Under normal circumstances, the electronic products we use are designed by PCB plus various electronic components such as Electronic Resistor and Capacitor according to the designed circuit diagram, so all kinds of electrical appliances need a variety of different SMT chip processing techniques to process.

1. Silk screen: Its function is to leak solder paste or patch glue onto the PCB pads to prepare for the soldering of components. The equipment used is a screen printing machine (screen printing machine), located at the forefront of the SMT production line.

2. Dispensing: It is to drip glue onto the fixed position of the PCB board, and its main function is to fix the components on the PCB board. The equipment used is a glue dispenser, located at the forefront of the SMT production line or behind the testing equipment.

4. Curing: Its function is to melt the patch glue, so that the surface assembly components and the PCB board are firmly bonded together. The equipment used is a curing oven, located behind the placement machine in the SMT production line.

5. Reflow soldering: Its function is to melt the solder paste, so that the surface assembly components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the SMT production line.

6. Cleaning: Its function is to remove the solder residues such as flux that are harmful to the human body on the assembled PCB board. The equipment used is a washing machine, and the location may not be fixed, it may be online or offline.

Contact us if you need more details on Pcba One-stop Service. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PCB Surface Mount、PCB Design One-stop Service. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : PCB Assembly Products > PCBA One-stop Service